Standard designs of threading tools

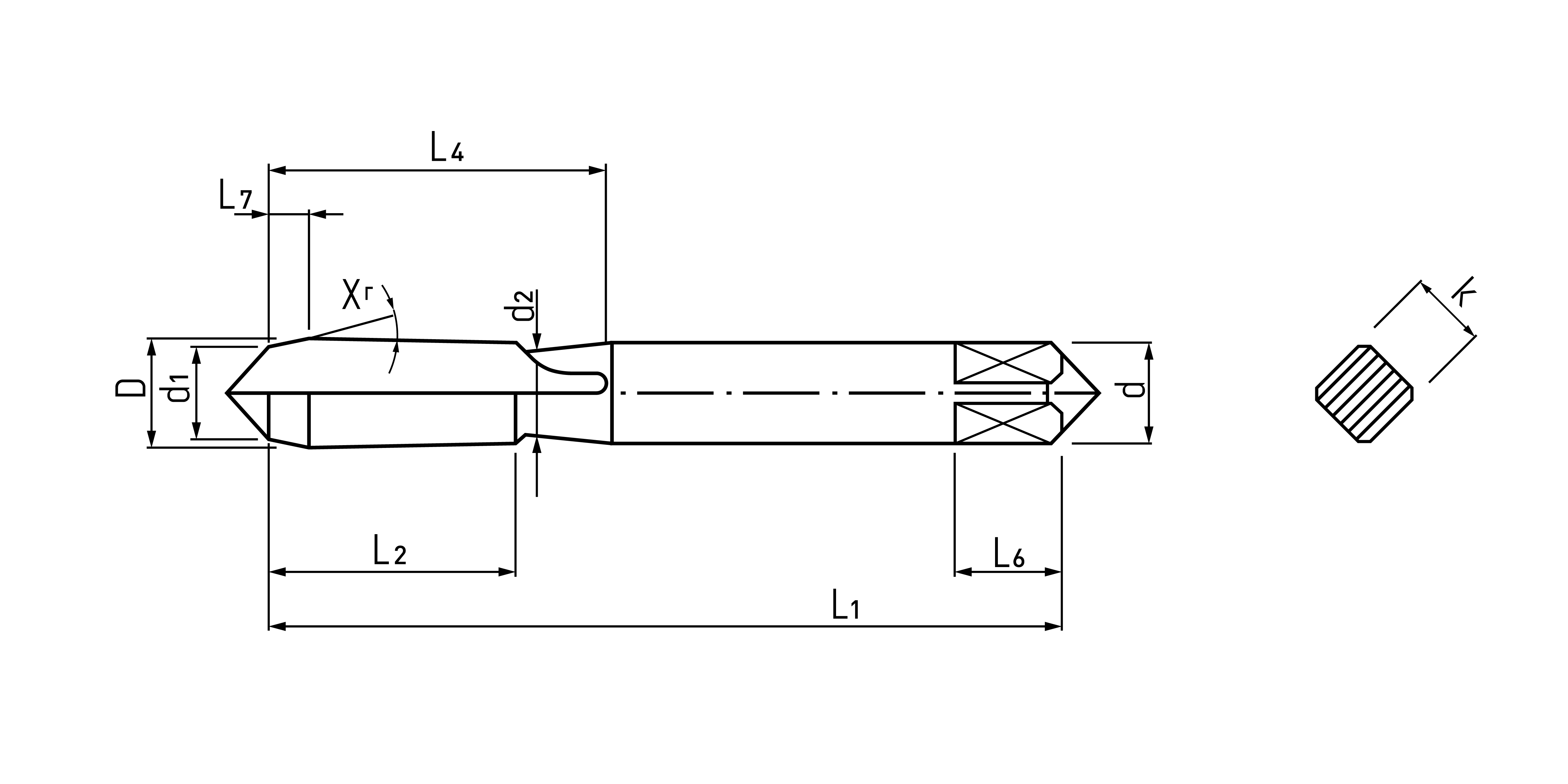

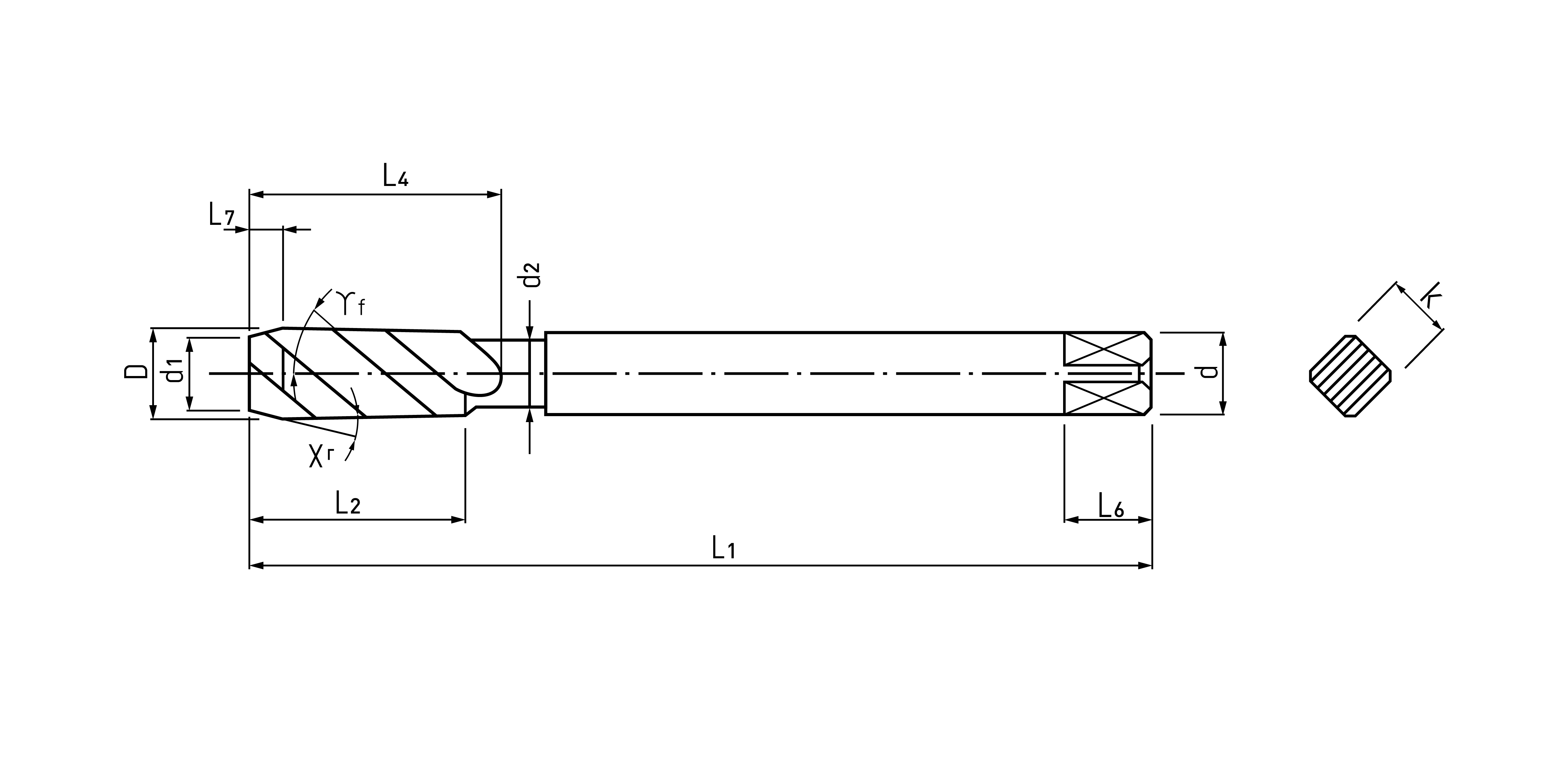

Hand tap

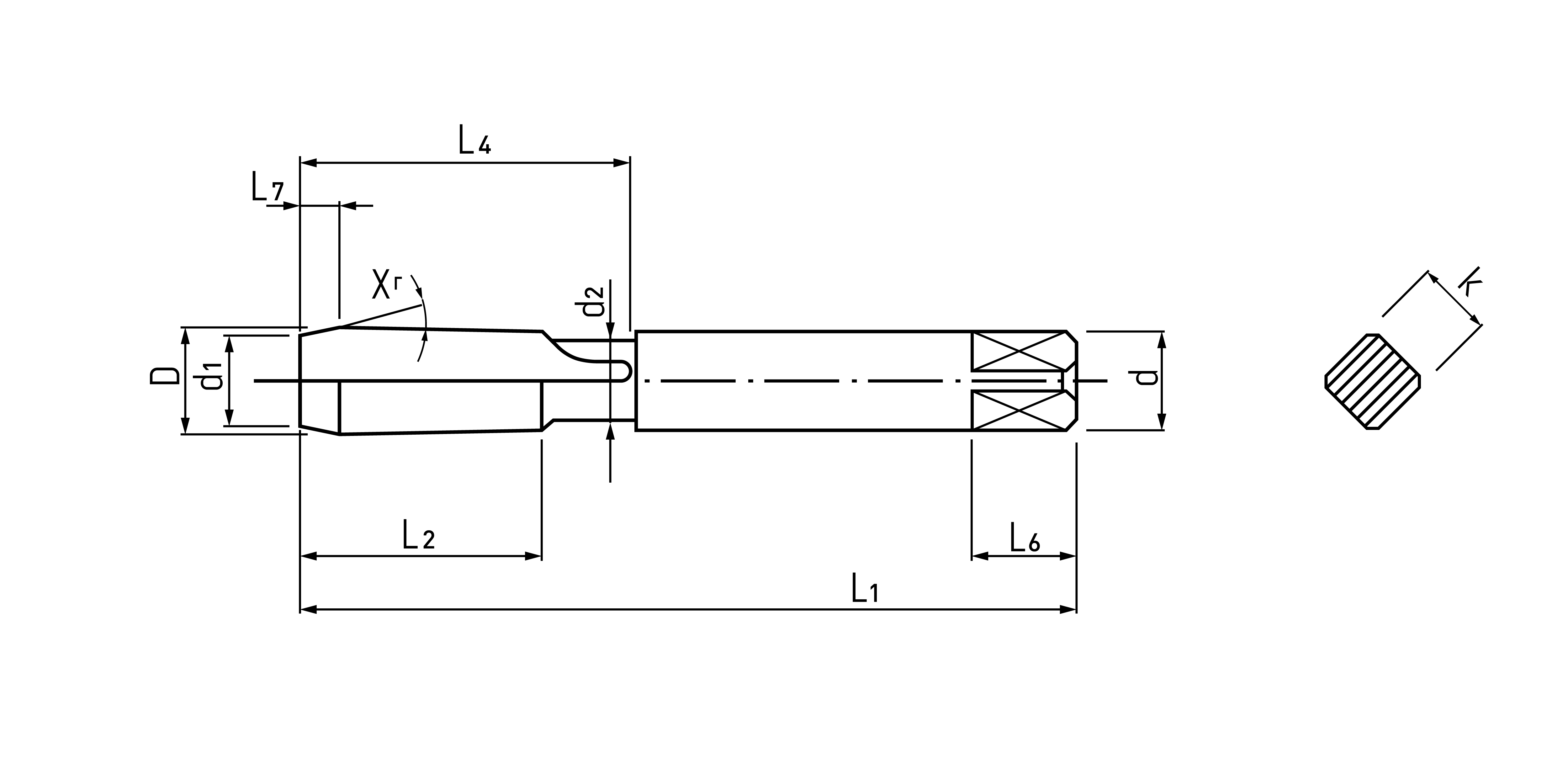

Hand tap 2-piece 3-piece with points DIN 2184-2

Hand tap 2-pcs. 3-pcs. without points DIN 2184-2

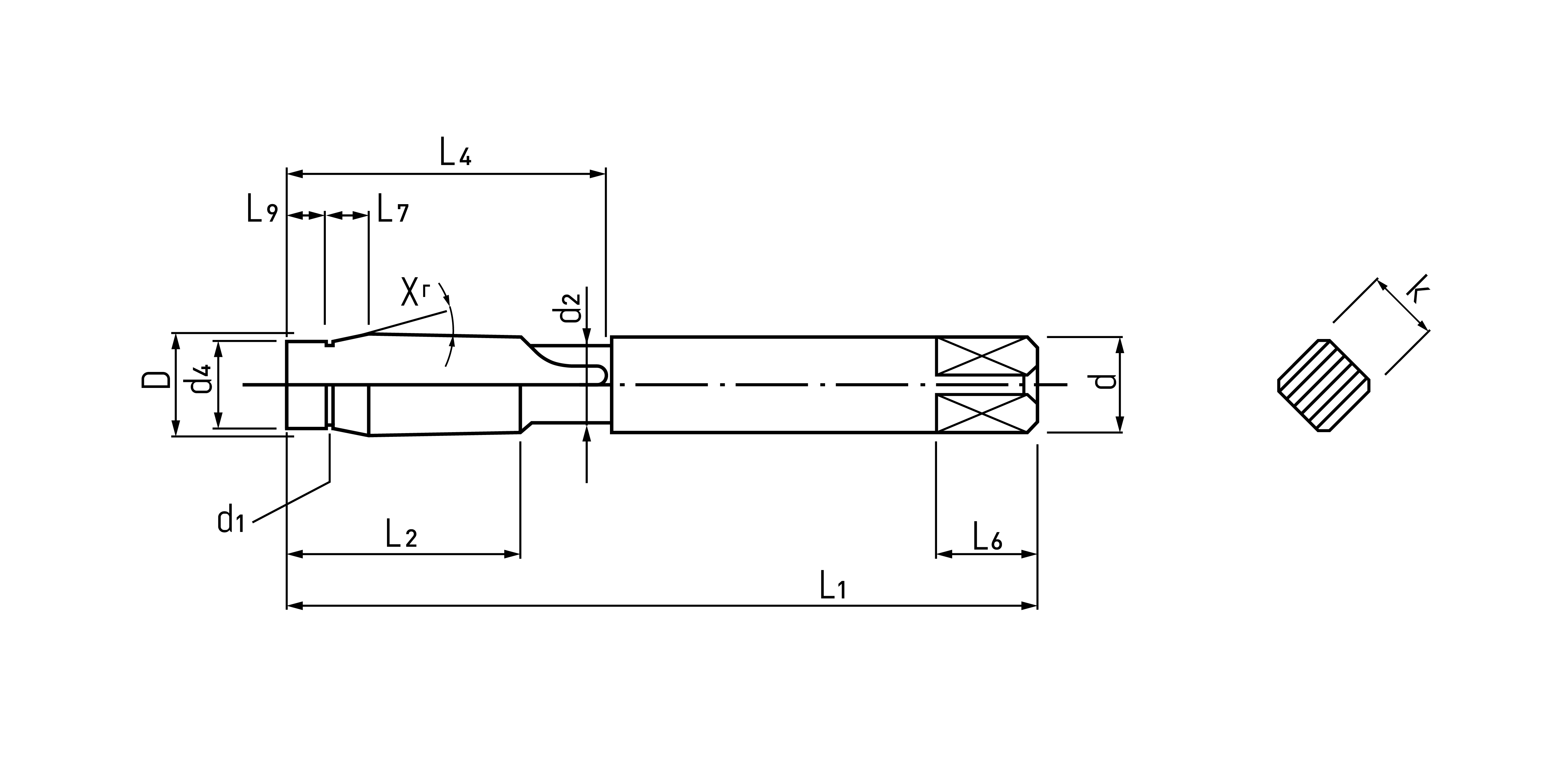

Hand Tap Pre-Tap with Guide Pin Factory Standard

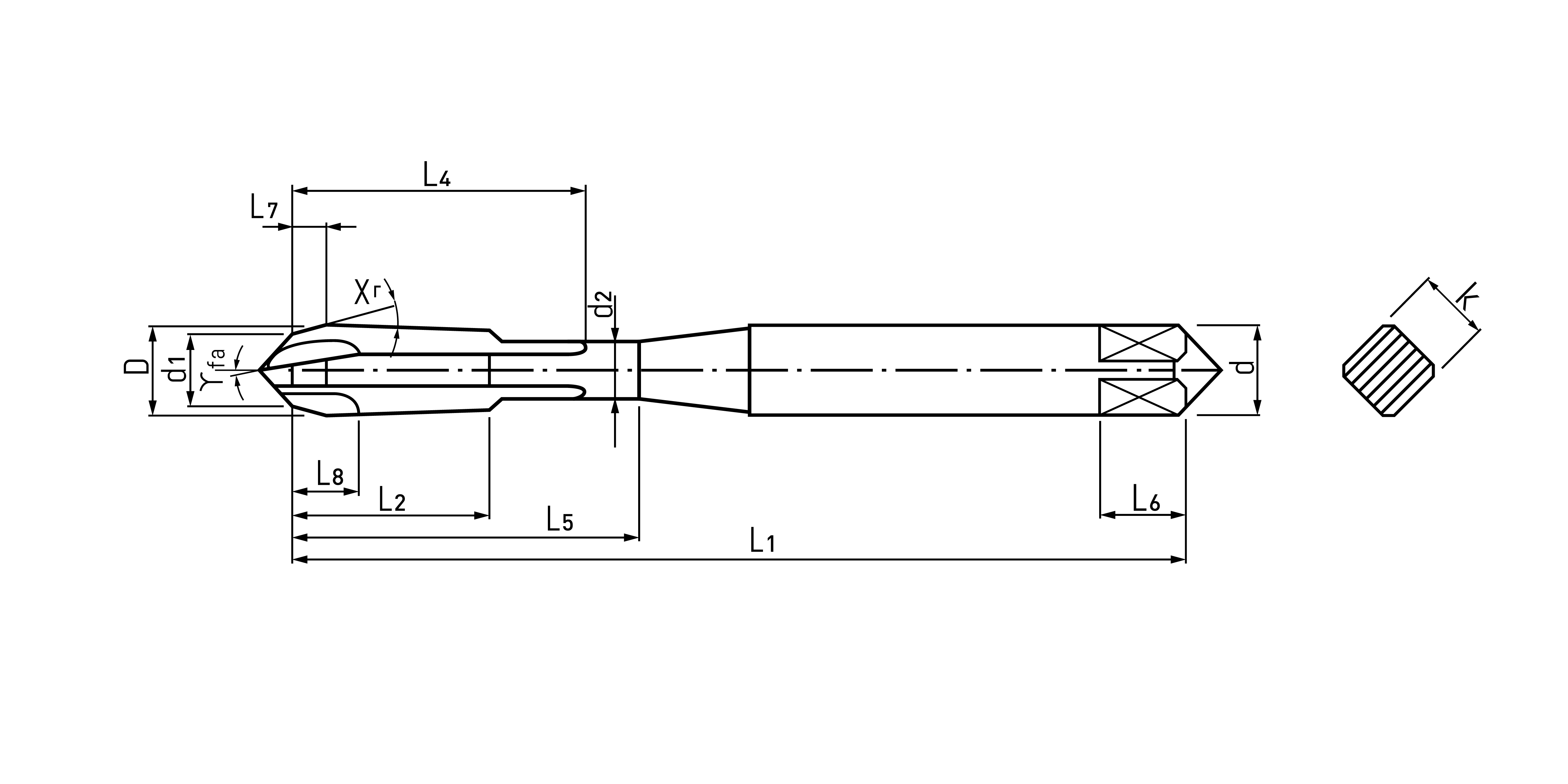

Hand tap

L1 = Total length

L2 = Thread length

L3 = Thread length at RSP>30°

L4 = Groove length

L5 = usable length (reinforced shank)

L6 = Square length

L7 = Gate cut length

L8 = Peel gate length

L9 = Guide pin length

d = Shank Ø

d1 = gate Ø

γf = helix angle

γfa = Peel cut angle

d2 = neck Ø

d3 = core-Ø

d4 = guide pin-Ø

k = square

Xr = setting angle

EXPLANATION OF SIGNS

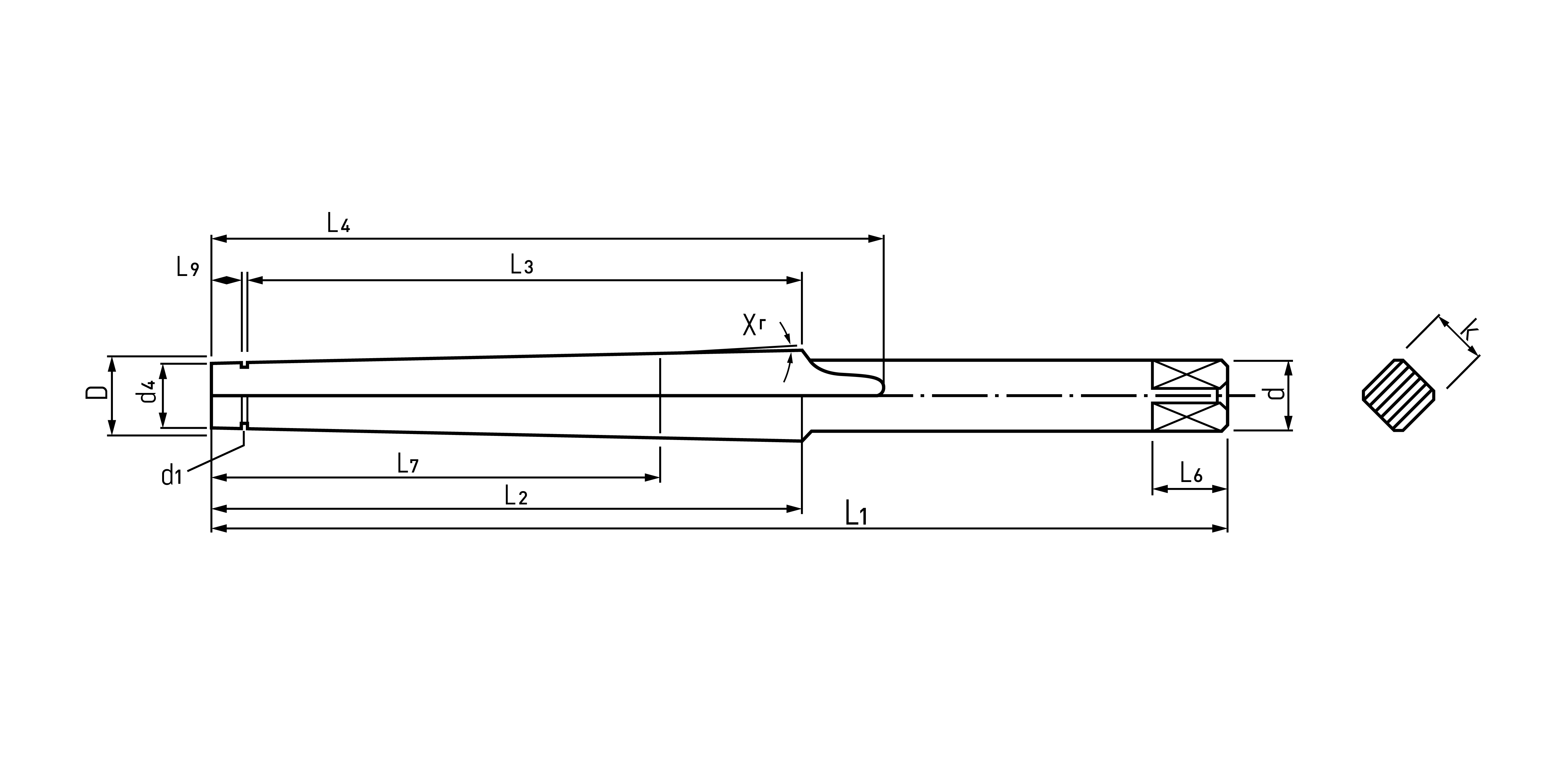

Machine tap

With reinforced shank, straight flutes and peel cut DIN 2184-1

With overflow shank and approx. 35° right-hand helical grooves DIN 2184-1

Machine nut tap with long lead DIN 357

Machine tap

L1 = Total length

L2 = Thread length

L3 = Thread length at RSP>30°

L4 = Groove length

L5 = usable length (reinforced shank)

L6 = Square length

L7 = Gate cut length

L8 = Peel gate length

L9 = Guide pin length

d = Shank Ø

d1 = gate Ø

γf = helix angle

γfa = Peel cut angle

d2 = neck Ø

d3 = core-Ø

d4 = guide pin-Ø

k = square

Xr = setting angle

EXPLANATION OF SIGNS

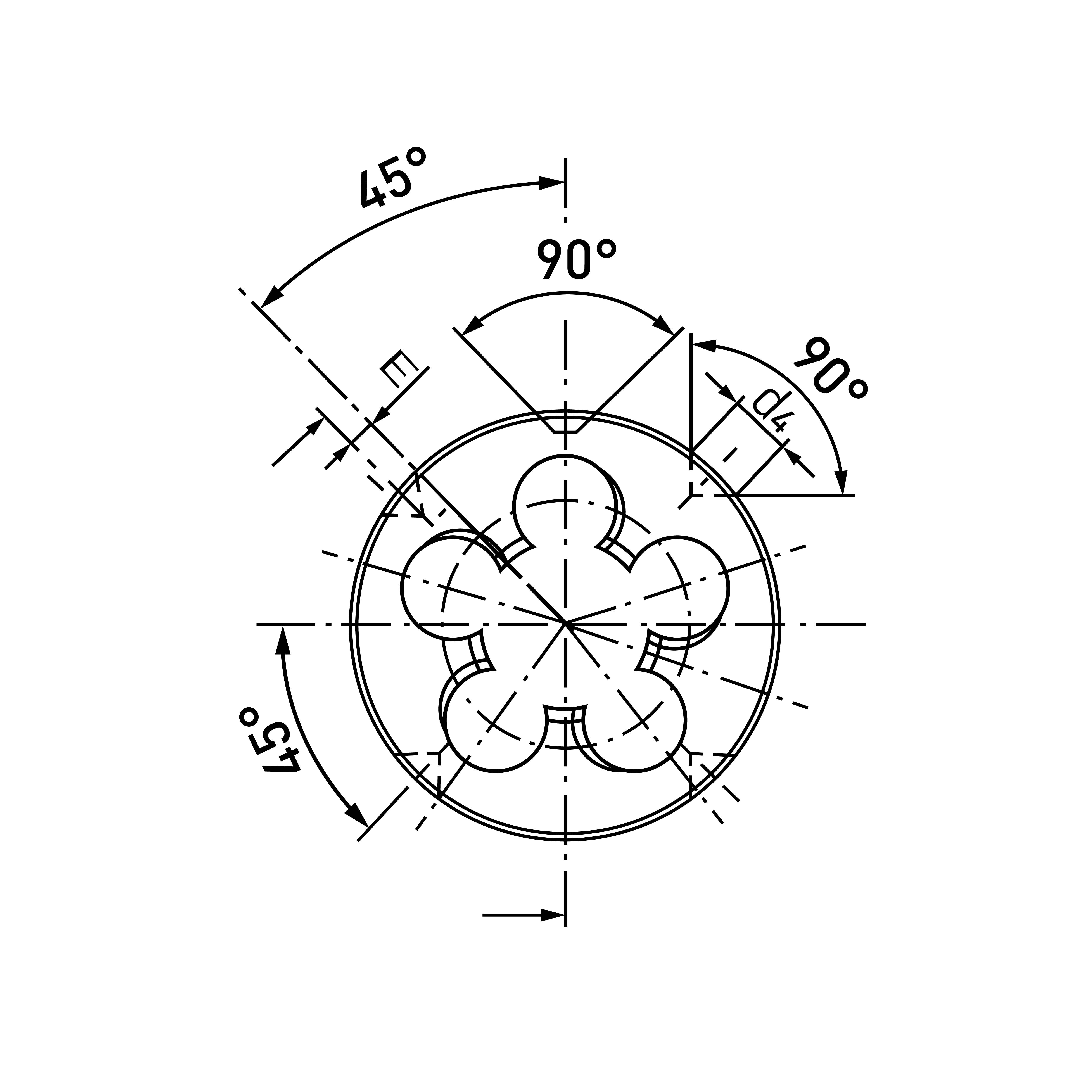

Die

Dies according to EN 22568 and EN 24231

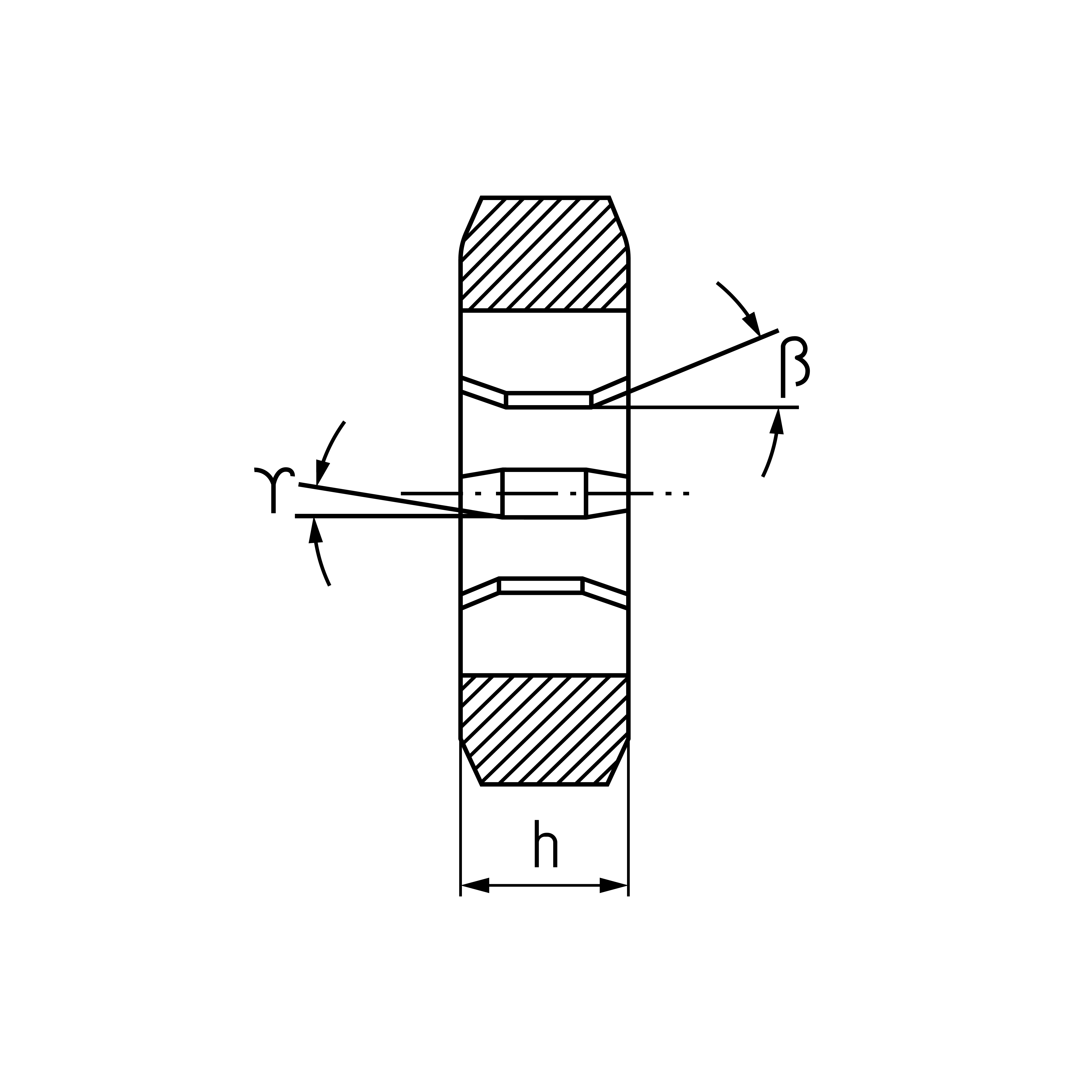

Dies EN 22568 and EN 24231 side view

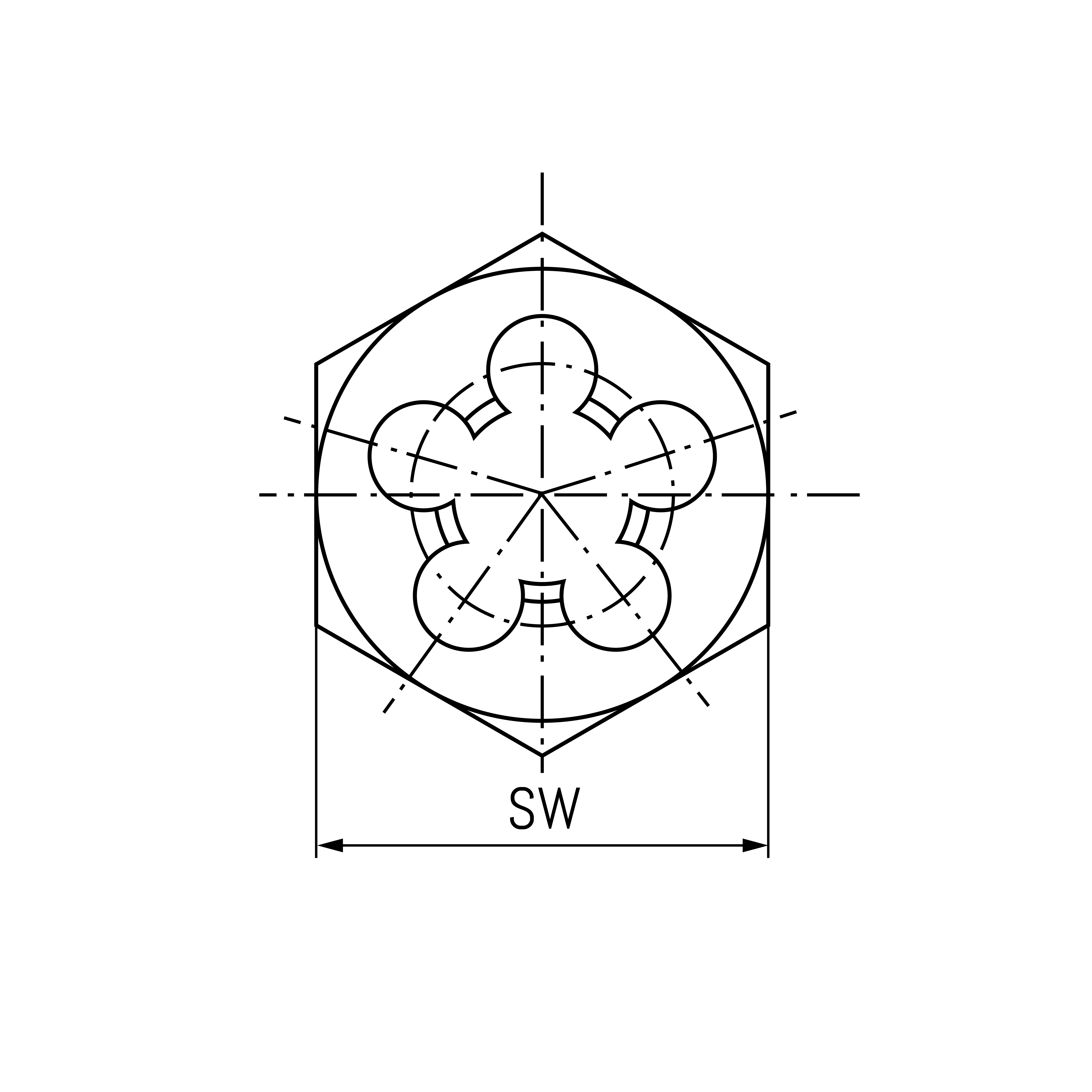

Hexagonal bar according to DIN 382

Hexagonal cutter according to DIN 382 Side view

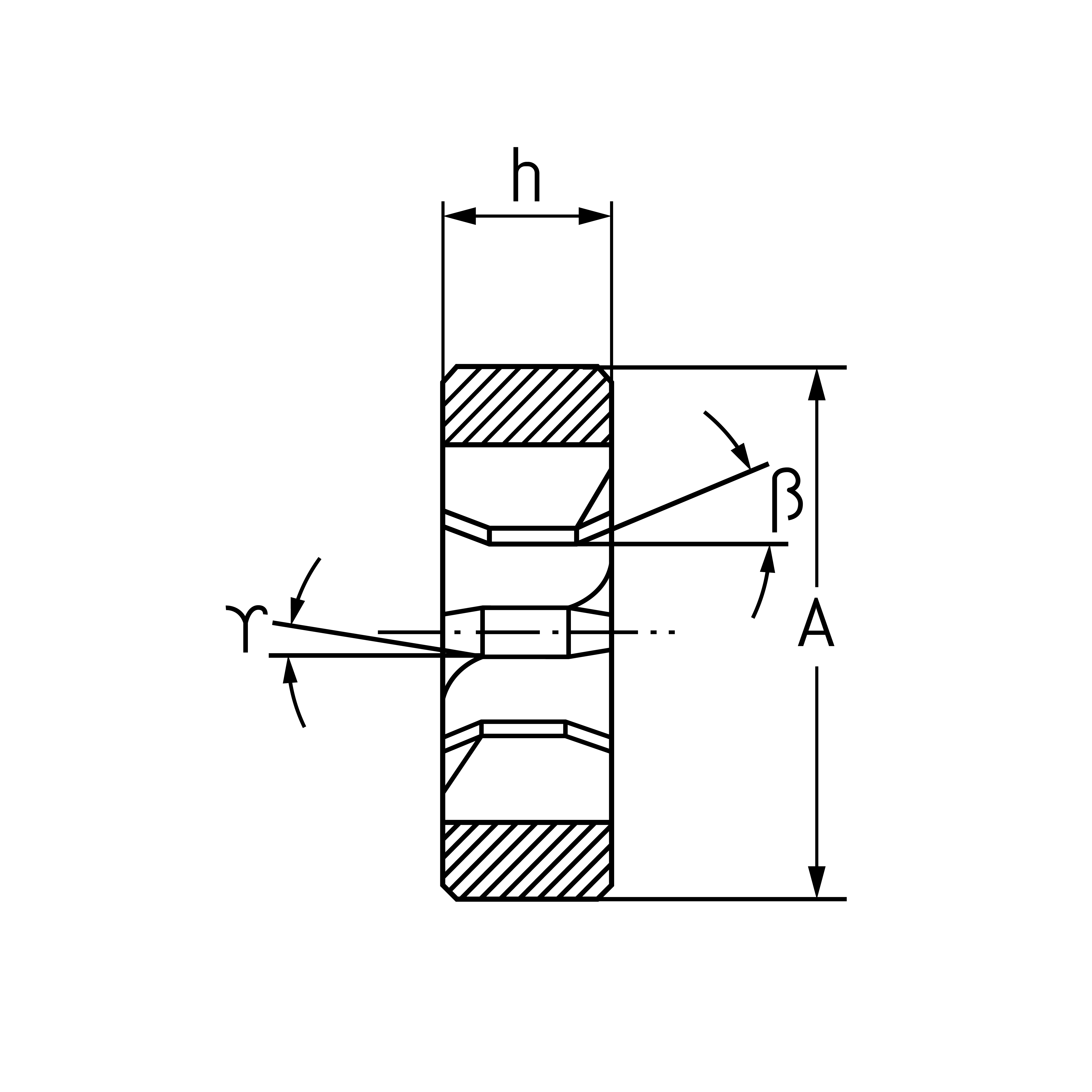

Cutting irons and hexagonal cutting irons

A = Outer Ø

SW = Width across flats

h = height

ß = gate angle

γ = Peel gate angle

d4 = Chip hole Ø

EXPLANATION OF SIGNS